|

|

August 12, 2014 |

|

J.D. Cousins EconoCooler for furnace cooling at new high-tech silicon metal manufacturing facility

J.D. Cousins, a leading designer and manufacturer of heat exchangers since 1904, has been selected to engineer, design, and manufacture a large submerged arc furnace cooler for Mississippi Silicon in Burnsville, Mississippi.

READ MORE

|

August 12, 2014 |

|

J.D. Cousins, Inc. and EvapTech, Inc. announce a joint marketing agreement to provide energy efficient industrial closed loop evaporative fluid coolers.

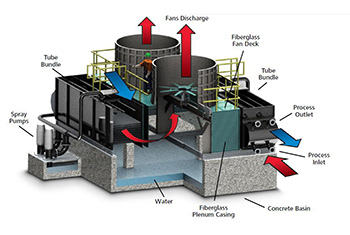

J.D. Cousins, Inc. and EvapTech, Inc. today announced a strategic partnership to co-market EconoCool, a closed-loop industrial evaporative cooler product. The EconoCool technology is a highly-efficient, cost-effective solution for large scale cooling of fluids that provides engineers and owners with many benefits.

READ MORE

|

November 13, 2013 |

|

Closed-Loop Evaporative System Touted for Process Fluid Cooling

A closed-loop evaporative system employing a single-step process is a more effective and efficient method of cooling process fluids or condensing gases than a conventional two-step process such as an open cooling tower and a separate heat exchanger. This is according to Buffalo, N.Y.-based J.D. Cousins Inc., which developed and has released the EconoCool technology.

READ MORE

|

August 06, 2013 |

|

J.D. Cousins, Inc. Introduces EconoCool: Alternative to Conventional Cooling Tower Technology

EconoCool is a closed loop evaporative cooling technology for lower-cost and

more effective process fluid cooling and gas condensing than a cooling tower and

heat exchanger combination.

READ MORE

|

Discover News at J.D. Cousins |

|

J.D Cousins recently completed three separator tanks for a Southern refinery. This job was challenging due to its size, quality assurance requirements and tight delivery schedule.

The carbon steel Tanks were 84” in diameter x 22’ long and 5/8” thick, with a weight of 20,000 lbs. In addition, we were required to perform 100% x- ray on all welded joints, post-weld heat treat, ultrasonic testing, liquid penetrant, magnetic particle testing, hardness testing of the welds. Many fabrication shops would have difficulty handling the major size and quality assurance requirements, in addition to a difficult delivery schedule. Normally, a job with these requirements would take approximately 24 weeks, but the customer absolutely needed them completed in 12 weeks. J.D Cousins was able to meet the challenge due to our commitment to outstanding customer service.

We will work just as hard to earn your business as well.

|

|

|

|

|